A problem with LEGO trains is that the wheels of the waggons and non-powered axles of the locos do not have ball bearings. This creates a lot of drag on the axles, resulting in slow or stuck trains, especially in curves.

There are two options to overcome this problem:

- Adding more motors, power and/or weight to your locos,

- reducing drag with ball bearings.

Obviously, the second option is far more intelligent.

Research results

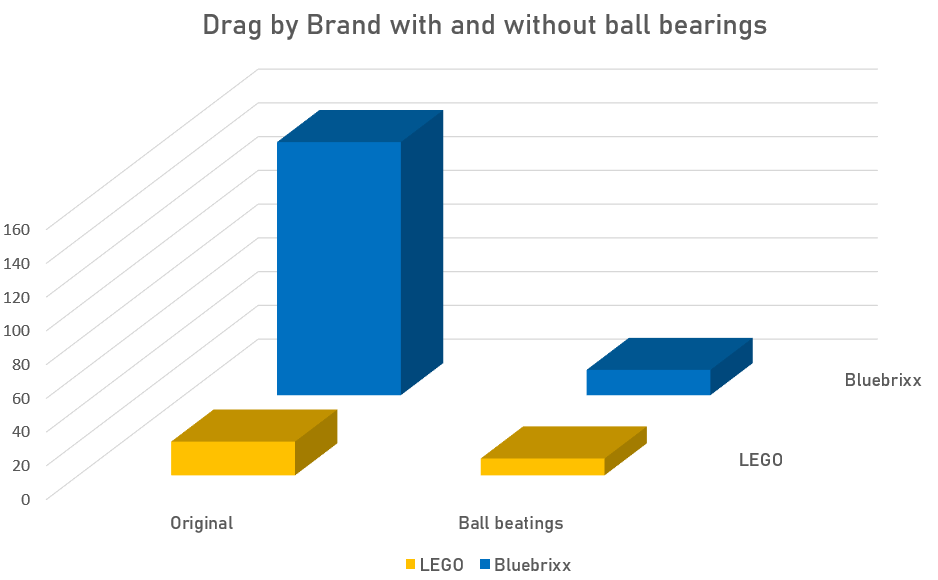

Our experiments have shown the following results:

- Without ball bearings, original LEGO wheel sets have significantly less drag than third-party wheel sets.

- Ball bearings reduce drag by about 50% compared to original LEGO train wheel sets.

- Ball bearings reduce drag by about 90% compared to third party wheel sets.

- When using ball bearings, the performance different between LEGO train wheel sets and third party train wheel sets is about 30%. That means that using ball bearings reduces the performance difference between original LEGO wheel sets and third-party wheel sets significantly.

- The ability to pass tight curves with low drag is substantially improved by using ball bearings.

The following diagram shows the results of a large series of tests runs with various cars and wheel sets.

The research was done for standard wheel sets only. The experiments were performed with LEGO and Bluebrixx wheelsets.

Practical example given: I needed four motors for my legacy Rheinhold train (modified Bluebrixx BR01 steam loco plus with five modified Bluebrixx waggons, each weighing more than 630g) to be able to move it at all. With ball bearings, the whole train can be operated with a single motor on straight rails, and with only two motors even though tight curves.

Summary: ball bearings bring you to a new level of LEGO train operation.

Required material

Before discussing the different ways of integrating ball bearings into your LEGO train wheel sets, here is the list of materials that you need.

The required material for all methods is:

- 2 ball bearings type MR52ZZ per axle,

- 1 axle 40mm x 2mm

Some methods or situations require additional material – see below!

Purchase info: Bill of material.

The LEGO axles have the same dimension, but in practice they are some 1/100 millimeters wider than the axles as recommended on the bill of material page. You need a lot of force to put the ball bearings on the original axles by using a hammer, which may damage the ball bearings. This is the reaon why we recommend to use the alternative axles. The same applies for axles of other vendors like Bluebrixx – it is better to use the alternatives axles as they fit better!

Types of Ball Bearings

1. Standard wheel sets

The standard wheel sets were sold by LEGO until about 2022. These wheel sets have a steel axle. They were replaced by new plastic train wheels in 2022 as can e.g. be found in LEGO set no. 60337.

Third party providers like Bluebrixx are likely going to sell this old but established wheel sets for a longer period in the future.

In the next sections, three different methods of fittings these wheel sets with ball bearings.

Method 1: The grub screw method

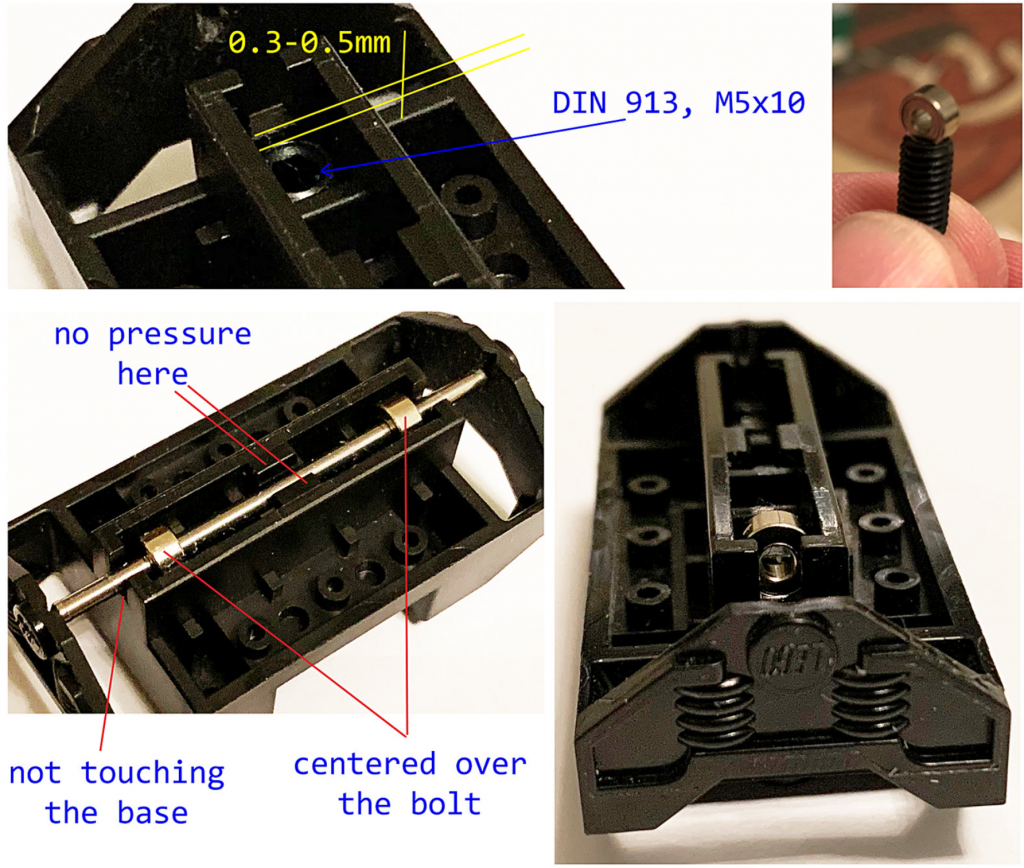

In addition to the ball bearings and the axle, you need 2 grub screws M5x10 per axle.

The grub screws must be screwed into the wheel holder that they are exactly 4,5mm lower than the lower part of the wheel holder. You can measure this with a precise slide gauge.

The ball bearings must have a distance of exaclty 7mm from the end of the axle.

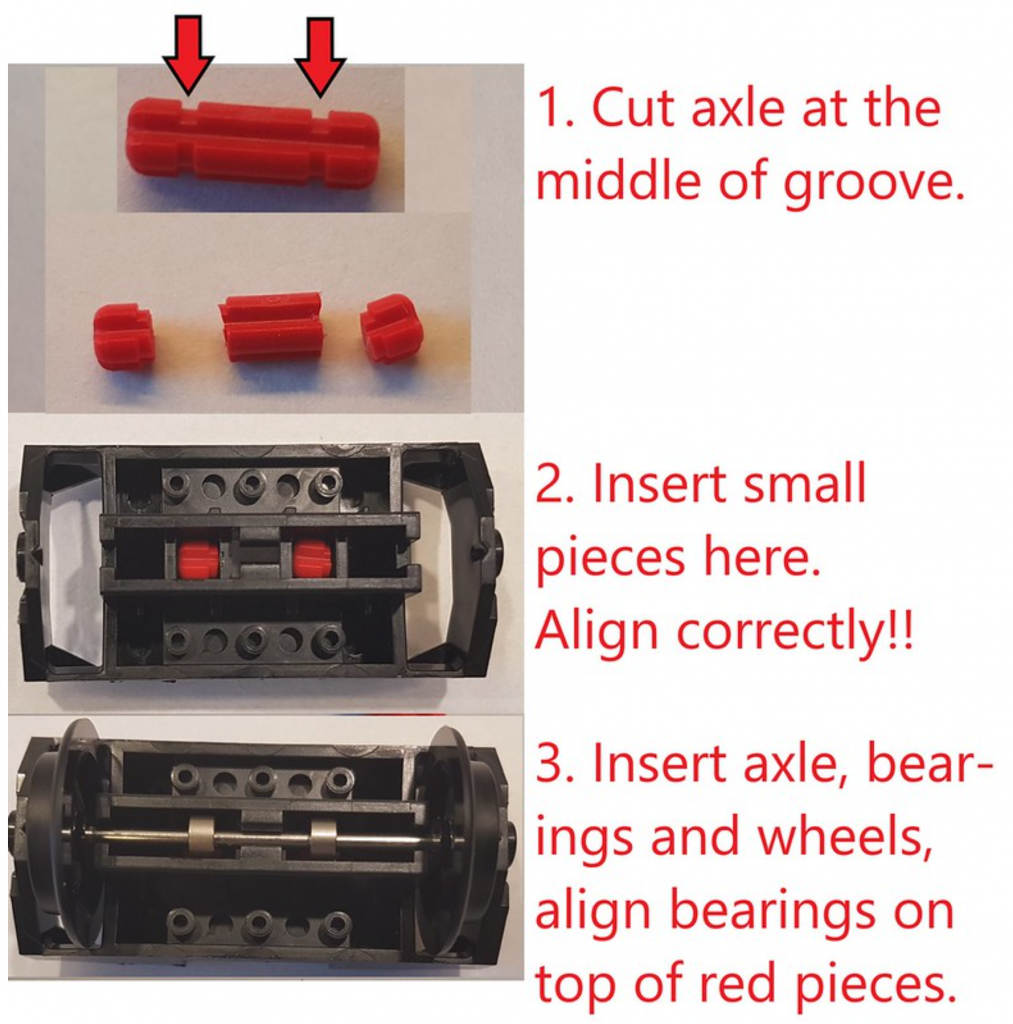

Method 2: The 2L axle method

In addition to the ball bearings and the axle, you need a 2L Technic Axle.

The Technic axle must be cut to a length of around 3,8mm.

Attention: once the piece of the Technic axle is in the wheel holder, it will stay inside. It is very hard or impossible to get it out again. So expect this method to be a one-way ticket for your wheel holder.

Option 3: The milling method

In this method, the side part of the wheel holder is milled or cut out.

Summary: which method is the best?

The best method is in our view option 1 (the grub screw method).

These are the reasons:

- The method yields the overall best performance / lowest drag.

- The method does not destroy the wheel holder. You can bring the wheel holder in its original condition any time (with scratches in the area of the grub screws of course).

- No LEGO parts must be destroyed.

- The height of the axle can be adjusted by turning the grub screws. You can do this until you have found the perfect position with the lowest drag.

- The axles have a very good hold in the wheel holder. The axle keeps its position also in tight and fast curves.

- After a bit of experience, this method is the quickest to build.

Drawbacks of method 2 (2L axle method):

- Axle is not adjustable in height.

- Ball bearing supports are quite in the middle of the axle. If loaded heavily, the axle bends, and the axle tends to move in tight and fast turns.

- Once the technic axle is installed in the wheel holder, it is practically stuck there forever.

Drawbacks of method 3 (milling method):

- LEGO parts get hurt.

- By cutting the sides of the wheel holder of, the axle looses lateral support. The axle can break out to the side in tight curves of in crash situations.

- You need a lot of precision and time to get the axle into the correct position.

2. Technic Wheel sets

Some LEGO or brick wheels are constructed without the standard wheel sets. A common example can be found in locomotices that have one motor on one side a blind, unpowered wheel set on the other side.

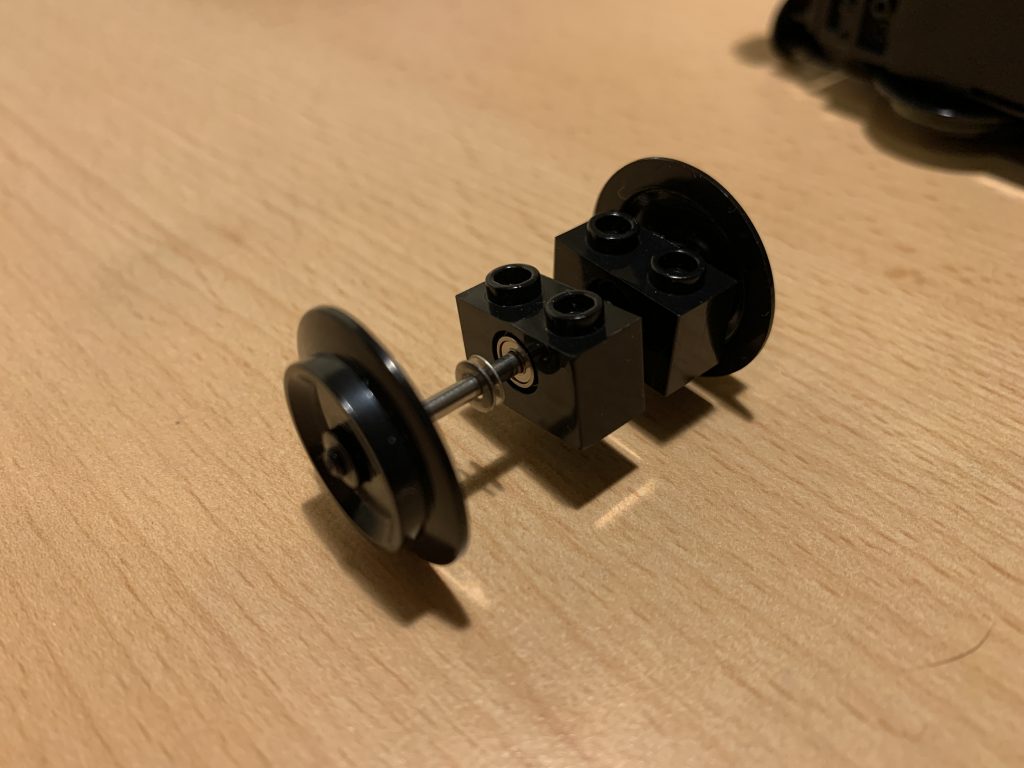

The following picture shows such a wheel sets which we call “technic wheel set”:

The reason for this name comes from the construction of the wheel set – it is build with technic bars. LEGO technic axles (6L) serve as train wheel axles.

The following picture shows a technic wheel set. The right axle is still a technic 6L axle, the left one has already been replaced by a steel axle with ball bearings.

The ball bearing is located in the technic bar. In the example this is a Technic brick 1×2 wit hole (part 3700). As a side note, the construction is more solid if you use Technic bricks 1×8 (part no. 3702) instead.

To mount the ball bearing into the Technic brick, no drilling is required. The only thing you need is a bench vice to generate enough force to press the ball bearing into the brick. Make sure that the ball bearing is absolutely in level with the side of the Technic brick.

It is required that you mount two or three flat washers between the ball bearing and the train wheel. This is important that the wheels do not drag on the side of wheel set in curves.

Media

I have created videos about ball bearings for LEGO and brick trains in English and German. Enjoy!

English version

German version

Credits

Pepe Nietnagel [Flickr].